news

Today we will look at common brand foosball manufacturing process

Author: Dinibao release time:2020-06-18 17:27:22CTR:

Making dolls

Melt the aluminum bar and start the journey of soul. First, you have to endure the hardships of 660 ℃

In the first mock exam, the injection mold is used to melt molten aluminum into the mold. In order to improve efficiency, the mold design of the small piece products is a multi cavity mold, which provides the basic shape. This process is very similar to that of Zha Zha.

The product injected under high pressure will be a little rough

Workers put the casting into a punch press, one press can separate four dolls, and remove the redundant burr at the same time

The computer-controlled drilling machine drills holes in the center of the doll for the ball bar, and then holes for screws that can be fixed on the back of the doll.

Another machine cuts a gap on the back of the doll, which can adjust the tightness of the doll on the club.

After completion, the puppet will be painted and colored. First, apply a layer of primer. After the primer is dry, use the spray gun to color the puppet.

The spraying process is totally different from what I originally thought. It's a simple clip that covers the parts of the doll that don't need painting, and only colors the jerseys and socks. The color of the other parts below is also assisted by the paint cover plate

If the manufacturer needs, it can spray different skin color dolls

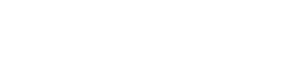

Making a table

The material of the table is solid beech. The milling machine cuts out the shape of wooden parts, drills necessary holes and engraves the name of the manufacturer.

Frame assembly

Assemble the ball table from four sides of the ball table, fix the shape with steel frame, lock the bolt and apply glue to ensure the integrity of the frame.

Wooden supporting rod is installed inside, and the connection is fixed with shooting nails, so that the ball table is more solid and stable

Spraying treatment

This style will be painted with red paint in the side grooves and trademark lines, depending on the color of the ball table or the original color of the wood

All the tables will be painted with a transparent varnish to protect the wooden parts and increase the hand feel.

When the ball is shot into the hole, it will roll back to the center on the curved ball back to the ball bottom plate, and enter the aluminum ball taking slot. After the gluing bottom plate is installed, the bottom is finished.

Component assembly

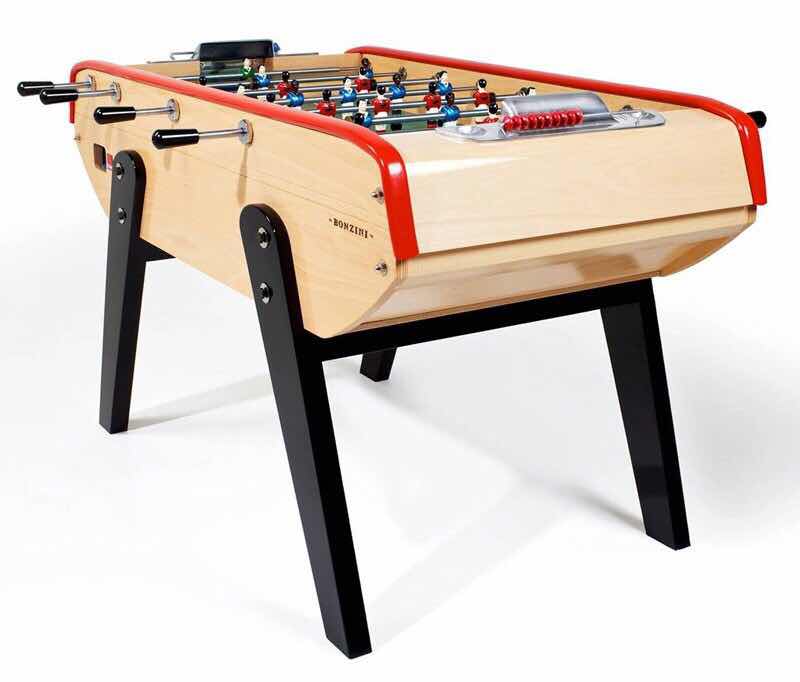

The workers turned the table to the right, installed the aluminum goal and the scorer, and then installed the green vinyl plastic board and the ball table panel made of density board on the wooden support.

The wooden decorative strips around will fix the surface of the ball table

Install a string of dolls on a hollow stainless steel strip

Use the template to adjust the clearance, then fix the dummy on the club with screws, and then install the rubber buffer on the most peripheral dummy on both sides of the club.

Then a thin stainless steel strip is inserted into the hollow ball bar to make the ball bar stretch.

Workers put the clubs on the table

The extension end of the ball bar is equipped with a spring bearing, which can fit into the hole on the side of the ball table, and fix the ball bar from the outside.

At last, the workers installed protective plastic strip on the edge of the table, plastic grip on the telescopic end of the ball bar, and four solid wooden foot stands for the table.

Now we can have a wonderful football match on the table.

Previous:Is the car game the same as the Simulator racing car arcade game machine?

Next:What precautions should be taken when installing a carousel?

relevant information

- Main selling points of Super Street Fighter IV fighting video game machine

- It's no accident that lipstick prize gift machine will catch fire

- Detailed teaching of toy grabbing machine

- How to play the amusement game machine well?

- Bumper car battery car does not need special site configuration

- The short characters in arcade games

- The status quo of the makers of arcade games

- New machine recommendation: dazzle basketball

- Master wearing dinosaur clothing scared two ha, but the result was "see through", dog: how old still play

- What should be paid attention to when purchasing new design 12p Murray go round carousel