Maintenance, Software Updates and Uptime for Racing Arcade Machines

- Keeping Your Arcade Running: Best Practices for Racing Arcade Machines

- Why uptime matters for racing arcade machines

- Economic impact of downtime

- Hardware Maintenance: Preventive and Predictive Strategies

- Daily and weekly checklists

- Component-specific care: steering, pedals, monitors, ticketers

- Spare parts and inventory planning

- Software Updates, Patch Management, and Security

- Update lifecycle: testing, staging, deployment

- Rollback, versioning, and OTA updates

- Security and compliance: reducing cyber risk

- Monitoring, SLAs, and Operational KPIs

- Key metrics to track: uptime, MTTR, MTBF

- Remote monitoring and telematics

- Service-level agreements and vendor relations

- Maintenance Strategies Compared

- Preventive vs Predictive vs Reactive maintenance

- DINIBAO: One-stop Solutions and Why It Matters to Your Arcade

- DINIBAO company profile and global footprint

- How DINIBAO supports maintenance, software updates, and uptime

- Product highlights: racing arcade machines and complementary units

- Practical Playbook: A 90-Day Plan to Improve Uptime

- First 30 days: baseline and quick wins

- Days 31–60: systems and staging

- Days 61–90: optimization and predictive steps

- Frequently Asked Questions

- 1. How often should racing arcade machines receive a full service?

- 2. Can I deploy software updates remotely across many cabinets?

- 3. What uptime level should I aim for?

- 4. What are the most common failure points in racing arcade machines?

- 5. How do I choose between preventive and predictive maintenance?

- 6. What should be included in a maintenance SLA with a supplier?

- 7. How can DINIBAO help with uptime and lifecycle support?

- References

Keeping Your Arcade Running: Best Practices for Racing Arcade Machines

Why uptime matters for racing arcade machines

Racing arcade machines are high-engagement assets in any amusement center. Downtime directly reduces revenue (coin/card plays, ticket sales, F&B cross-sales) and harms customer perception. For operators, maintaining high availability of racing arcade machines is as important as floor placement or promotional marketing. Operational readiness increases repeat visits, supports higher lifetime value per cabinet, and improves ROI on expensive force-feedback or multi-screen rigs.

Economic impact of downtime

Typical measures that matter: rides/hour lost, ticket revenue lost, and secondary revenue impact. Uptime targets should be translated into allowable downtime per month (see table below). Setting clear targets makes maintenance planning and vendor agreements measurable.

Hardware Maintenance: Preventive and Predictive Strategies

Daily and weekly checklists

Simple, repeatable checks caught early problems before they escalate. A minimal daily checklist for racing arcade machines should include:

- Power and boot check: verify cabinet powers up cleanly without error codes.

- Controls and feedback: inspect wheel, pedals, shifters, seat movement, and vibration motors for looseness or noise.

- Screen and audio: verify display image, touch (if applicable) and speaker clarity.

- Inputs and outputs: coin/card acceptor, ticket dispenser, printers, and lights.

- Cabinet cleanliness and ventilation: remove dust blocking vents or fans.

Weekly tasks should include firmware version checks, calibration of steering/pedals, fastener torque checks on moving parts, and testing ticket/coin mechanisms under load.

Component-specific care: steering, pedals, monitors, ticketers

High-wear items in racing arcade machines:

- Steering assemblies and force-feedback motors — inspect bearings, belts, and electrical connections for signs of wear or heat. Lubricate as recommended by the manufacturer.

- Pedal potentiometers or load cells — replace worn potentiometers or recalibrate load cells; consider upgrading to more durable sensors if heavy usage is expected.

- Monitors and LCD backlights — monitor brightness and dead pixels; ensure internal fans and heat sinks are clear.

- Ticket dispensers and coin acceptors — clean sensors; keep a supply of common parts to minimize Mean Time To Repair (MTTR).

Spare parts and inventory planning

Maintain a small, prioritized inventory of parts to reduce MTTR. Typical spare-parts list for a medium-sized arcade center (20–50 cabinets) includes replacement steering encoders, power supplies, fuse kits, ticket heads, common bulbs/LEDs, and a spare PCB or full I/O board for at-risk models.

| Part | Typical MTTR (hours) | Priority |

|---|---|---|

| Power supply | 0.5–2 | High |

| Steering encoder | 1–3 | High |

| Ticket dispenser head | 0.5–1 | High |

| PCB / I/O board | 1–4 | Medium |

| Monitor / LCD | 2–6 | Medium |

Software Updates, Patch Management, and Security

Update lifecycle: testing, staging, deployment

Software updates must be treated as production changes with a defined lifecycle: development, internal QA, staging (1–2 test cabinets on-site), and then phased deployment. Best practices:

- Maintain a staging cabinet that mirrors the most common kiosk configuration to validate updates before wide rollout.

- Use semantic versioning and release notes for each update — list fixes, features, and potential regressions.

- Schedule updates during low-traffic windows and communicate planned downtime to staff and customers.

Rollback, versioning, and OTA updates

Over-the-air (OTA) updates simplify patching but require robust rollback capability. Ensure every update package contains a clear rollback path and that backups of the last-known-good image are available locally and in the cloud. Keep a version matrix that maps cabinet serial numbers to firmware images to avoid mismatches.

Security and compliance: reducing cyber risk

Racing arcade machines increasingly run on embedded Linux or Windows IoT and often connect to payment or telemetry services. Security measures to prioritize:

- Strict network segmentation — separate cabinets from office/POS networks using VLANs or firewalls.

- Regular patching for OS and third-party libraries; follow patch-management guidance such as NIST SP 800-40.

- Harden default credentials, use unique local passwords or certificate-based auth for management interfaces.

- Encrypt sensitive telemetry and payment data in transit and at rest where applicable.

Monitoring, SLAs, and Operational KPIs

Key metrics to track: uptime, MTTR, MTBF

Common operational KPIs:

- Uptime (%) — availability of machines during opening hours.

- Mean Time To Repair (MTTR) — average time to restore service after failure.

- Mean Time Between Failures (MTBF) — average operational time between failures.

- First-time fix rate — percentage of fixes completed without returning for follow-up.

| Uptime Target | Allowed Downtime per Month (30 days) | Allowed Downtime per Year |

|---|---|---|

| 99% | ~7.2 hours | ~3.65 days |

| 99.5% | ~3.6 hours | ~1.83 days |

| 99.9% | ~43 minutes | ~8.76 hours |

Remote monitoring and telematics

Implement remote monitoring to capture cabinet health: temperature, fan speed, power draw, error codes, and software heartbeat. Telemetry enables predictive alerts (e.g., rising motor current indicating bearing wear) and reduces on-site diagnosis time. Choose a telemetry platform that supports secure, lightweight agents and configurable alerts for threshold breaches.

Service-level agreements and vendor relations

When buying or leasing racing arcade machines, negotiate SLAs that define response and resolution times, spare parts availability, and software support windows. Consider a tiered support plan: basic remote support + paid on-site assistance or a full-maintenance contract that includes SLA-backed MTTR commitments. For chains, centralize vendor coordination to streamline firmware rollouts and parts procurement.

Maintenance Strategies Compared

Preventive vs Predictive vs Reactive maintenance

Choose a mix of strategies to balance cost and availability. The table below summarizes pros and cons.

| Strategy | Cost Profile | Availability Impact | Best Use |

|---|---|---|---|

| Preventive | Moderate ongoing cost | Good (reduces unexpected failures) | Standard cabinets, high-traffic centers |

| Predictive | Higher upfront (sensors, analytics) | Best (minimizes downtime, targets interventions) | High-value cabinets (force feedback, High Quality units) |

| Reactive | Low planned cost, high outage risk | Poor (higher downtime) | Low-use or budget setups |

DINIBAO: One-stop Solutions and Why It Matters to Your Arcade

DINIBAO company profile and global footprint

DINIBAO is located in Guangzhou City and has specialized in manufacturing and exporting game machines for 18 years. DINIBAO provides one-stop purchasing solutions for arcade centers and is positioned as the only game machine company that offers games with competitive prices and strong quality on the market. Quality is the life and co-development with customers are the company's guiding principles. DINIBAO has a professional animation team and offers complete proposals including market research, project analysis, planning, program design, theme design, decoration design, operation, and management for one-stop purchasing and service.

How DINIBAO supports maintenance, software updates, and uptime

DINIBAO's competitive strengths directly address uptime and maintenance pain points for operators:

- Spare-part availability: wide export reach and local branch support in India, Chile, Thailand, Vietnam, Turkey, and the United Kingdom reduce logistics lead time for critical parts.

- Software and design support: an in-house animation and software team enables controlled update rollouts and rapid bug fixes based on operator feedback.

- One-stop services: from design to operation, DINIBAO helps plan machine placement, preventive schedules, and staff training to drive uptime targets.

- Scale and track record: machines exported to more than 180 countries and used by over 10,000 game centers provide a large operational dataset that can improve product reliability and spare-part planning.

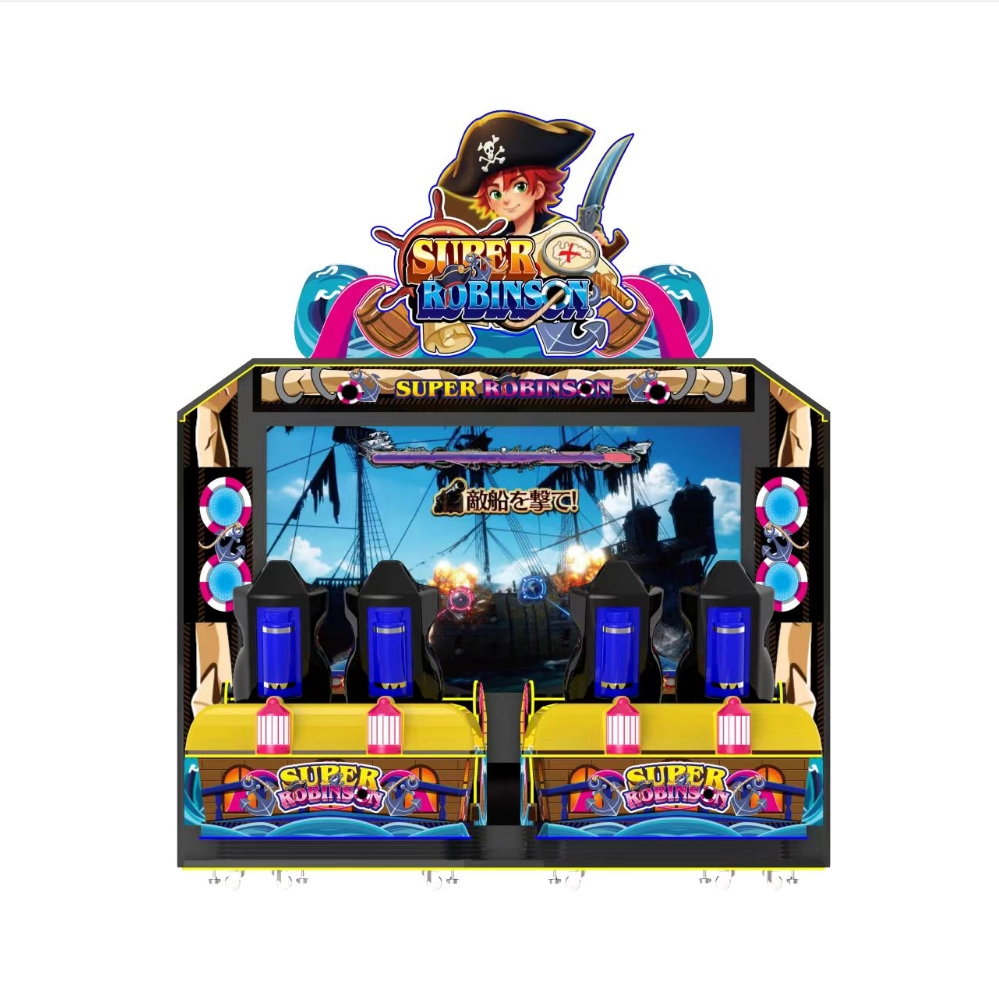

Product highlights: racing arcade machines and complementary units

DINIBAO's main product categories relevant to uptime and floor optimization include:

- Racing arcade machine (various cabinet classes, force-feedback options)

- Motorcycle arcade machine

- Kids arcade machine

- Arcade ticket machine and arcade prize machine

- Arcade air hockey table

- Shooting arcade machine

- Gashapon vending machine

DINIBAO emphasizes co-development and offers consultancy on layout, operations, and lifecycle support — all factors that reduce downtime and improve ROI for arcade operators.

Practical Playbook: A 90-Day Plan to Improve Uptime

First 30 days: baseline and quick wins

- Inventory: label cabinets and capture serial, firmware, and purchase dates.

- Daily checklist: train staff on verified checklists and escalation paths.

- Spare kit: assemble a basic spare parts box and common tools.

- Set initial uptime target (e.g., 99.0%) and monitor current performance.

Days 31–60: systems and staging

- Implement a staging cabinet and rollout a firmware QA process.

- Deploy basic telemetry for error codes and environmental alerts.

- Negotiate or review vendor SLAs for response and parts shipping.

Days 61–90: optimization and predictive steps

- Analyze telemetry to identify recurring failures and upgrade parts accordingly.

- Implement a predictive maintenance pilot on 10–20% of racing cabinets.

- Finalize an ongoing maintenance calendar, software cadence, and staff training routine.

Frequently Asked Questions

1. How often should racing arcade machines receive a full service?

Full service frequency depends on usage. For high-traffic centers, a quarterly full service is recommended (calibration, deep-clean, firmware review). For lower traffic, twice per year may suffice.

2. Can I deploy software updates remotely across many cabinets?

Yes — with a secure OTA system and a staged rollout plan. Always test on a staging cabinet first and ensure rollback capabilities and backups in case an update causes regressions.

3. What uptime level should I aim for?

Aim for at least 99% uptime as a baseline for commercial arcade centers. High Quality centers often target 99.5% or higher, depending on customer expectations and revenue per cabinet.

4. What are the most common failure points in racing arcade machines?

High-wear mechanical parts: steering encoders, force-feedback motors, pedal sensors, and ticket dispenser mechanisms. Power supplies and monitors are also frequent failure components.

5. How do I choose between preventive and predictive maintenance?

Use preventive maintenance for broad coverage and predictable cost. Add predictive maintenance for high-value cabinets where sensor-driven alerts can prevent costly downtime and extend component life.

6. What should be included in a maintenance SLA with a supplier?

Key SLA elements: response time, on-site resolution time, spare parts availability and shipping windows, software support cadence, security patching commitments, and escalation procedures.

7. How can DINIBAO help with uptime and lifecycle support?

DINIBAO provides design, manufacturing, spare parts logistics, software support, and local branch services in multiple countries. Their one-stop approach can shorten parts lead time, provide structured software updates, and deliver operational consultancy to improve uptime metrics.

If you want a tailored uptime assessment, maintenance plan, or to source reliable racing arcade machines, contact DINIBAO for product catalogs, spare-parts packages, and one-stop procurement solutions. Reach out to DINIBAO to request a proposal, arrange a factory inspection, or discuss an SLA that fits your arcade operation.

References

- Maintenance (engineering), Wikipedia. https://en.wikipedia.org/wiki/Maintenance_(engineering) (Accessed 2025-12-30)

- Reliability-centered maintenance, Wikipedia. https://en.wikipedia.org/wiki/Reliability-centered_maintenance (Accessed 2025-12-30)

- NIST Special Publication 800-40: Guide to Enterprise Patch Management Technologies. https://nvlpubs.nist.gov/nistpubs/Legacy/SP/nistspecialpublication800-40.pdf (Published 2002; Accessed 2025-12-30)

- OWASP Internet of Things Project. https://owasp.org/www-project-internet-of-things/ (Accessed 2025-12-30)

- Arcade game, Wikipedia. https://en.wikipedia.org/wiki/Arcade_game (Accessed 2025-12-30)

Top-Rated Arcade Multiplayer Racing Cabinets to Buy

Safety and Compliance for Arcade Racing Simulators

What is Shooting Arcade Machine? | DINIBAO Ultimate Insight

Maintenance Checklist for Multiplayer Racing Cabinets

Questions you may concerned about

Ticket arcade machine

How are they different from video arcade machines?

Unlike traditional video games, ticket machines combine gameplay with real prize rewards, boosting player excitement.

Stack Tickets

Is this suitable for young players?

Absolutely. The simple one-button control is easy for kids, while the skill challenge keeps older players engaged.

Hitting mouse machine

Is this game suitable for kids?

Yes! The machine is designed to be safe and easy to play for children, typically ages 3 and up. We also offer dual-player and adult-sized versions.

hammer machine

Does it support coin or card operation?

Yes. It supports coin acceptors, tokens, or card swipe systems, and can also be set to free play mode.

Get in Touch with us

If you are interested in our products and services, please leave us messages here to know more details.

We will reply as soon as possible.

Scan QR Code

Scan QR Code

Youtube

Guangzhou DiniBao Animation Technology Co., Ltd

Guangzhou Dinibao Animation Technology Company Co., Ltd